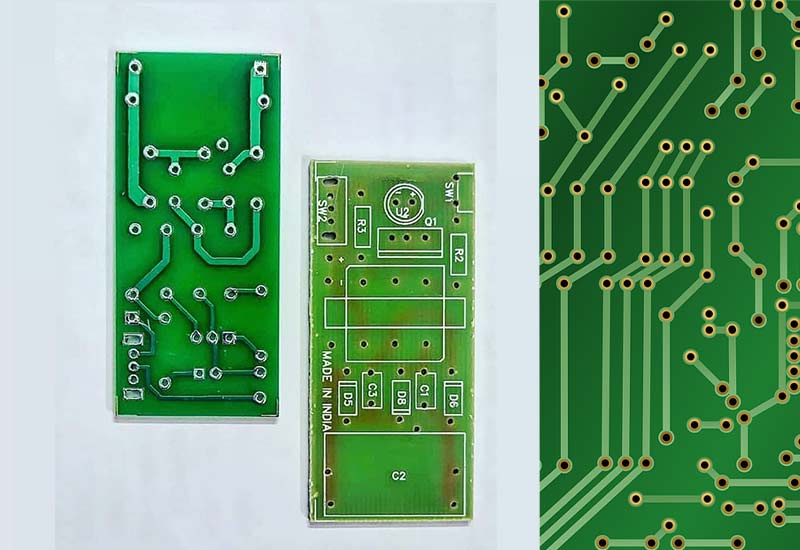

Single Sided PCB

Single-sided Printed Circuit Board comes with a layer of conductive material on one side and on the other side of the board and Surface-mount technology capabilities are there. This kind of PCBs fulfills the requirement of mechanical strength and a variation of pads and traces to permit for a wide range of electronic parts to be put on. Some advantages of these types of PCB; It is Perfect for simple low-density designs, cost-effective, Popular, common, minor possibility of producing issues.

Single-sided printed circuit boards are regularly used in electronics and applications like; cameras, printers, radio equipment, calculators, and much more.

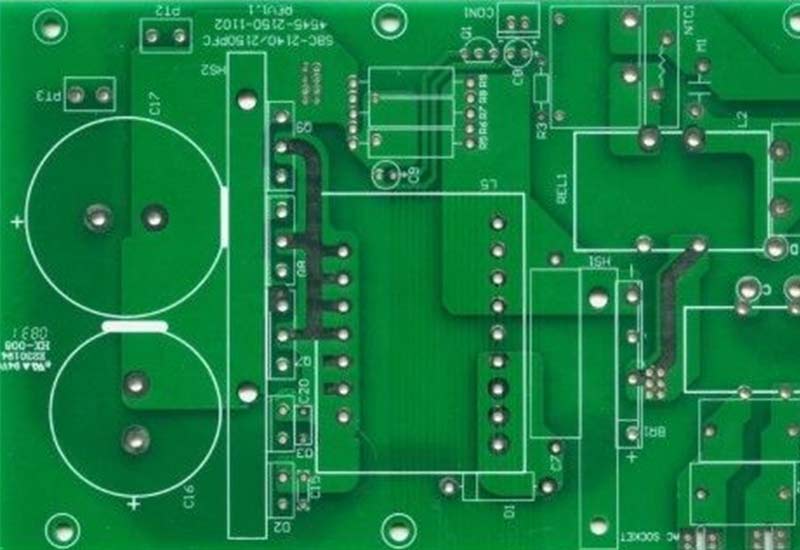

Double Sided PCB

Double-sided PCBs are extensively used all through the electronics industry. Double-Sided PCB also known as Double-Sided Plated by DSPT and the circuits are the doorway to the latest technology applications. They authorize for a closer routing trace by alternating between top and bottom layers using Virtual Integrated Design & Analytics Solutions.

These PCBs are recognized for their accuracy, constancy, flexible handling and cost-effectiveness notice a large requirement in the industry.

Some advantages of these types of PCB; It is more convertible to design, more compact circuit, cost-effective, transitional level of circuit density, the compact board size, etc.

Flexible PCB

Flexible PCBs are comprehensively used all through the electronics industry. This kind of PCB is a printed circuit manufactured on a flexible substance, manageable to be folded or bent to fix in a convenient space. we use the latest materials and PCB manufacturer standards to make our flexible circuits. Flexible PCBs are prominent when space is limited.

Some advantages of these types of PCB; With quality materials, reliable Flex circuits can be bent numerous times during fitting without circuit failure. Flexible circuits are widely used in consumer electronics, like cameras, cell phones, GPS, computer printers, medical devices, and calculators.

Rigid Flex PCB

Rigid-flex PCBs are electronic boards using a combination of flexible and rigid PCB board technologies in an application, most rigid-flex PCB consist of multiple layers of flexible circuit substrates attached to one or more rigid boards externally and/or internally, depending upon the design of the application. Rigid-flex design doesn’t just maximize space and weight but greatly improves reliability.

Rigid-flex PCBs are a combination of rigid and flexible PCBs. The combination enables the development of mechanically challenging designs. Rigid-flex PCBs can replace an older, more traditional combination of rigid PCBs, connectors, and cables. As the mechanical connections are reduced, the overall efficiency of electrical contacts is enhanced, and the flexible part protects the circuit from mechanical hazards.

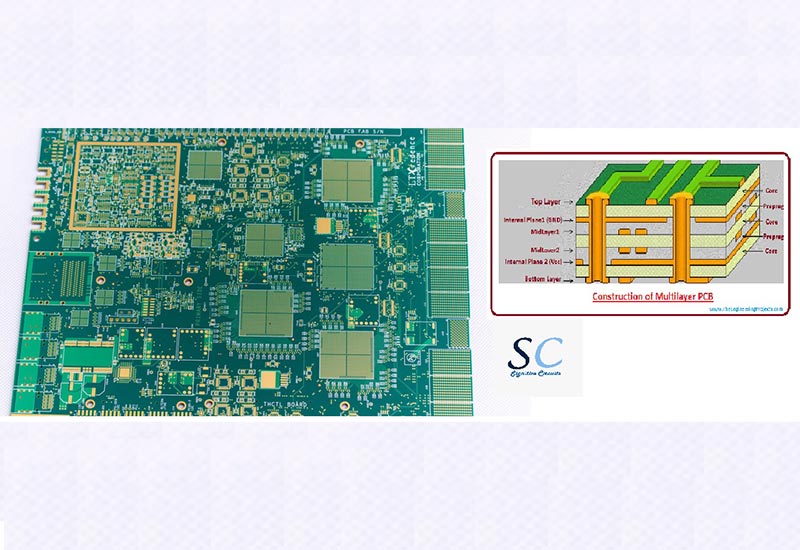

Multilayer PCB

This type of PCB is made up of more than two layers that is why it is called Multilayer PCB. It has using conductive copper foils and fibrous material, pressed and bonded together.

Multilayer is the most complicated printed circuit board by design and by production but it is the high speed by functionally. Currently, up to 40 layers of PCB is able to be done by using the latest machinery. These types of PCB are largely utilized in professional electronic equipment like computers, mobile, medical devices, aerospace, and defense application devices.

Some advantages of these types of PCB; are higher accumulation density, decrease size, increase flexibility, easier incorporation-controlled electric-resistance features, reduced need for interconnection, etc.

MCPCB

A Metal Core Printed Circuit Board is containing a base metal material. The core is designed to divert heat away from parts that bring out a considerable amount of heat. Indifference to FR4 and CEM3 printed circuit boards, a Metal Core Printed Circuit Board utilizes a base metal to enhance the thermal conductivity of the PCB. The metal core is composed of a metal plate with a proper thickness to vanish heat.

Some advantages of these types of PCB:- The main objective of an MCPCB is to vanish heat. This keeps away from the overheating of any parts that are set up to the circuit board and encircle hardware within the device that houses the MCPCB. It also sustains perfect levels of performance while enhancing the lifespan of the parts. A classic FR4 PCB is eight times less efficient at rapid heat transfer than a Metal Core Printed Circuit Board (MCPCB).

Due to the high degree of heat that is produced in particular applications, general cooling such as that consummate via fans may not be enough – in which case an MCPCB is a preferable alternative.

LED Tube Light –Owing to perfection and a quality-oriented approach, we have carved a niche in the industry by offering an enormous grade array of LED Tube Light MCPCB that includes LED Tube Light MCPCB. Our offered lights are manufactured with quality assured material and the latest technology. The offered range is availed in different sizes and other related specifications, to meet the needs of our prestigious clients.